CNC Machining for Rapid Prototyping: From CAD Design to High-Precision Finished Products

Jan 16, 2026

In modern manufacturing, CNC machining technology is not only the core process for producing complex parts, but also a key link from conceptual design to finished prototyping. Whether it is automotive components, aerospace structural components, or consumer electronic devices, prototyping is an indispensable part of the product development process. This article explores how CNC machining transforms conceptual designs into high-quality prototypes.

I. From concept to finished product: the whole process of CNC machining prototyping

1. Design and modelling

The first step in prototyping is design and modelling. With CAD software (e.g. SolidWorks, AutoCAD, Fusion 360), designers can convert abstract concepts into 3D models.

Key point:

Ensure geometric accuracy of the design model to avoid machining failures due to design flaws.

Add necessary process features (e.g. positioning holes, clamping surfaces) to facilitate subsequent machining.

2. Machining preparation

Before CNC machining, the design model needs to be converted into machinable NC code.

CAM software (e.g. Mastercam, UG NX, PowerMill) is used to generate machining paths and tool trajectories.

Tool selection: according to the material characteristics and machining requirements, select the appropriate tool (such as high-speed steel tools, carbide tools or diamond-coated tools).

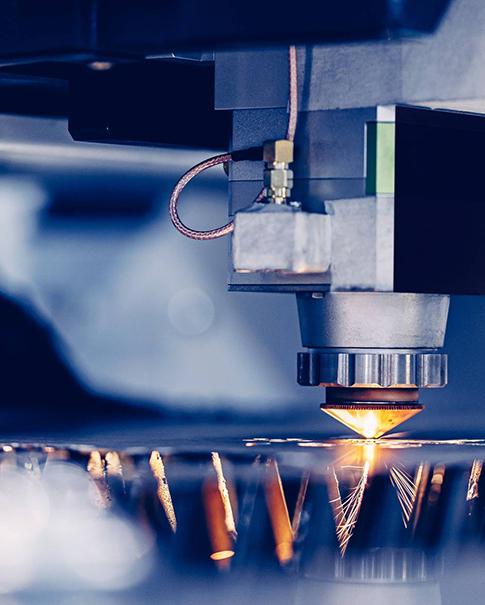

3. CNC machining

Prototype machining using high-precision CNC machines (e.g. 5-axis machining centres).

Optimisation of machining parameters:

Cutting speed, feed and depth of cut need to be dynamically adjusted according to material characteristics to ensure surface finish and machining efficiency.

Use multiple machining processes (roughing, semi-finishing, finishing) to gradually improve part accuracy.

4. Post-treatment

After machining, surface treatment (such as polishing, plating, anodising, etc.) is required to enhance the appearance and performance of the prototype.

II. Key technologies of CNC machining prototyping

1. High-precision machining

CNC machining technology can achieve micron-level machining accuracy (Ra ≤ 0.4μm), to ensure that the prototype is highly consistent with the design model.

Case: A medical device company uses a 5-axis machining centre to produce precision metal prototypes with a surface finish of Ra≤0.4μm, which meets medical grade standards.

2. Multi-material compatibility

CNC machining technology can process a variety of materials, including aluminium alloy, stainless steel, titanium alloy, plastics, etc., to meet the needs of prototypes in different industries.

Material selection:

Aluminium alloy: suitable for lightweight prototyping and low processing cost.

Stainless steel: suitable for high corrosion-resistant prototypes, with higher processing difficulty.

3. Rapid Prototyping

Through rapid prototyping technology (such as CNC machining combined with 3D printing), prototypes can be completed in a short period of time, shortening the product development cycle.

Case: a car manufacturer through CNC machining engine block prototype, from design to finished product in just 3 days.

III. CNC machining prototyping industry applications

1. Automotive industry

Application: engine block, gearbox shell, body structure parts of the prototype production.

Advantage: CNC machining can achieve high-precision processing of complex surfaces to meet the strict requirements of the automotive industry.

2. Aerospace industry

Application: prototyping of aircraft skin, engine blades, landing gear.

Advantage: CNC machining can process high-strength steel, titanium alloy and other difficult-to-machine materials to ensure the high strength and reliability of the prototype.

3. Medical equipment industry

Applications: prototyping of surgical instruments, orthopedic implants, and medical equipment housings.

Advantage: CNC machining can achieve high precision and high finish to meet the high cleanliness requirements of medical equipment.

4. Consumer Electronics Industry

Applications: prototyping of mobile phone shells, laptop shells, smart watch cases.

Advantage: CNC machining can achieve high-gloss chamfering and fine texture to enhance the quality of product appearance.

IV. How to choose CNC machining prototyping service providers?

1. Technical strength

Equipment: Choose a service provider equipped with high-precision CNC machine tools (such as five-axis machining centres) to ensure the machining accuracy and surface finish of the prototype.

Process: Choose a team with rich experience, able to optimise the processing parameters according to the material characteristics and design requirements.

2. Scope of service

Material selection: the service provider should support the processing of a variety of materials to meet different prototyping needs.

Post-processing: Provide polishing, plating, anodising and other surface treatment services to enhance the appearance and performance of the prototype.

3. Delivery cycle

Quick response: Choose a service provider that can quote and deliver quickly to shorten the product development cycle.

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER