Lavorare componenti metallici tramite CNC può sembrare semplice, finché non si incontrano vibrazioni, usura degli utensili o bordi che si fondono. Che si tratti della resistenza dell'acciaio inossidabile o della conduttività termica del rame, ogni metallo reagisce in modo diverso alla lavorazione CNC. Ecco perché comprendere come le macchine CNC lavorano con diversi materiali non è solo utile, ma essenziale.

In questa guida, analizzeremo come le moderne macchine CNC tagliano metalli comuni come acciaio, alluminio, rame e altri. Imparerai le tecniche, le sfide e le impostazioni delle macchine che fanno la differenza, oltre a quando è meglio esternalizzare la lavorazione dei metalli a professionisti specializzati nel farlo bene fin dal primo colpo.

Le macchine CNC possono tagliare il metallo?

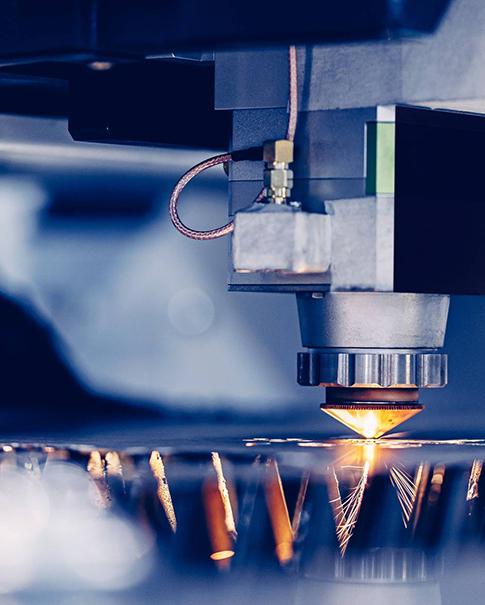

Assolutamente sì. Le macchine CNC sono progettate per tagliare i metalli con elevata precisione e ripetibilità. Che si tratti di una fresa CNC, di un tornio o di un sistema di taglio al plasma, la capacità di lavorare i metalli dipende dal tipo di utensile, dalla durezza del materiale e dalla rigidità della macchina.

Una macchina CNC può tagliare il metallo? Sì, ma non tutte le macchine sono uguali. Le macchine hobbistiche più leggere potrebbero avere difficoltà con i metalli più duri, mentre le macchine CNC di livello industriale sono progettate appositamente per gestire qualsiasi materiale, dall'alluminio morbido all'acciaio temprato.

Considerazioni chiave durante il taglio dei metalli:

● Utensili: gli utensili in metallo duro con rivestimenti come TiN o AlTiN aiutano a resistere al calore e all'usura.

● Velocità e avanzamento: per i metalli più resistenti sono necessari giri al minuto e velocità di avanzamento più bassi.

● Refrigerante: essenziale per la dissipazione del calore e la longevità dell'utensile.

Cerchi una lavorazione CNC affidabile per qualsiasi tipo di metallo? Richiedi un preventivo ai nostri esperti meccanici: sappiamo come gestire i tuoi componenti in acciaio, rame o alluminio senza compromessi.

Lavorazione CNC dell'acciaio: la forza incontra la strategia

È possibile lavorare l'acciaio con macchine CNC? Assolutamente sì. Infatti, è uno dei materiali più comunemente lavorati in ambito manifatturiero. Tuttavia, la tenacità dell'acciaio richiede un'attrezzatura più specifica.

Macchina CNC per acciaio: deve avere:

● Elevata coppia e rigidità del mandrino

● Serraggio corretto per ridurre le vibrazioni

● Liquido refrigerante per gestire l'accumulo di calore

Sfide dell'acciaio inossidabile:

● Tendenza a lavorare duro

● Rapida usura degli utensili

● Richiede utensili affilati e velocità ottimizzate

Per maggiori informazioni sulle tolleranze e le capacità CNC, consulta il nostro blog: Quanto è precisa la lavorazione CNC rispetto ad altri metodi di produzione?

Lavorazione dell'alluminio: velocità e precisione

L'alluminio è uno dei materiali preferiti per la lavorazione CNC grazie alla sua eccellente lavorabilità. È leggero, dissipa bene il calore e consente lavorazioni ad alta velocità con un'usura minima degli utensili.

Buone pratiche:

● Utilizzare RPM elevati per sfruttare la morbidezza

● L'evacuazione dei trucioli è fondamentale per evitare il ritaglio

● Considerare frese specifiche per alluminio per ridurre l'intasamento

Leghe come la 6061 e la 7075 sono ampiamente utilizzate nei settori aerospaziale, automobilistico e dei prodotti di consumo.

Rame e ottone: metalli teneri, sfide difficili

Il rame è un materiale conduttivo sia termicamente che elettricamente, il che lo rende ideale per l'elettronica, ma rappresenta una sfida per la lavorazione CNC. Tende a incollare gli utensili e a generare rapidamente calore.

Lavorazione del rame:

● Utilizzare utensili affilati e non rivestiti

● Applicare un refrigerante uniforme

● Velocità più basse per evitare il surriscaldamento

L'ottone, al contrario, è molto più facile da lavorare:

● La natura autolubrificante riduce l'attrito

● Formazione minima di bave

● Ideale per raccordi, oggetti decorativi e parti meccaniche a basso carico

Macchine CNC per il taglio dei metalli: differiscono in base al materiale?

Sì, una macchina CNC per il taglio dei metalli che lavora l'acciaio inossidabile avrà una configurazione diversa rispetto a una ottimizzata per l'alluminio. I fattori che variano sono:

● Coppia del mandrino vs velocità

● Strategia del percorso utensile (sgrossatura vs finitura)

● Rigidità dell'apparecchio

L'efficienza del taglio dei metalli con macchine CNC dipende in larga misura dall'abbinamento della macchina e degli utensili giusti con il metallo specifico.

Abbinamento dei metalli alle tecniche di lavorazione

Non tutte le macchine CNC sono adatte a tutti i metalli:

● Acciaio: frese o torni CNC con coppia elevata e refrigerante a flusso continuo

● Alluminio: fresatrici o router CNC ad alta velocità

● Rame/Ottone: Frese CNC standard con giri al minuto moderati e lubrificazione

| Metallo |

Usura degli utensili |

Velocità di lavorazione |

Qualità della finitura |

Punteggio di lavorabilità |

| Acciaio |

Alto |

Moderare |

Bene |

5/10 |

| Alluminio |

Basso |

Alto |

Eccellente |

9/10 |

| Rame |

Medio |

Basso |

Giusto |

4/10 |

| Ottone |

Basso |

Moderare |

Molto bene |

8/10 |

Perché conviene rivolgersi a esperti per la lavorazione CNC dei metalli

Ogni metallo ha le sue peculiarità. Dalla scheggiatura dei bordi sull'alluminio alla bruciatura degli utensili sull'acciaio inossidabile, una mossa sbagliata può rovinare un intero lavoro. Ecco perché è intelligente affidarsi a professionisti CNC esperti che sanno come ottimizzare le impostazioni, selezionare gli utensili giusti e fornire risultati precisi.

Conclusione

Lavorare i metalli con macchine CNC non significa solo avere la macchina giusta, ma anche saper lavorare con i punti di forza e i limiti di ogni tipo di metallo. Che si tratti della durevolezza dell'acciaio, della velocità dell'alluminio o della conduttività del rame, ogni materiale ha le sue best practice.

Per componenti ad alta precisione che richiedono qualità e coerenza, è opportuno collaborare con un servizio CNC che metta a disposizione una profonda competenza e gli strumenti giusti.

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER