Ti stai chiedendo Lavorazione CNC e perché è così importante nel mondo della produzione? Non sei il solo. La lavorazione a controllo numerico computerizzato (CNC) è un elemento chiave nella produzione moderna, poiché utilizza tecnologie avanzate per tagliare, modellare e creare componenti con precisione.

Questo articolo analizza le basi del funzionamento delle macchine CNC e il loro ruolo nella produzione di qualsiasi cosa, dai componenti per auto ai gadget tecnologici. Esamineremo anche i numerosi settori che si affidano a questa tecnologia e la sua importanza.

Panoramica della lavorazione CNC

La lavorazione CNC, controllata da computer, produce parti e componenti ad alta precisione. In questo processo, un programma computerizzato controlla il movimento degli utensili da taglio, che vengono poi gestiti dalla programmazione CNC per rimuovere il materiale dal pezzo in lavorazione e creare un pezzo finito.

La tecnologia CNC produce una vasta gamma di parti e componenti, inclusi quelli in metallo, plastica e altri materiali. Il processo può anche produrre parti con geometrie complesse e alti livelli di precisione, rendendolo una scelta popolare per applicazioni in numerosi settori, tra cui aerospaziale, automobilistico, dei dispositivi medici e dei prodotti di consumo.

Offre diversi vantaggi rispetto ai metodi di lavorazione tradizionali, tra cui maggiore precisione, uniformità e velocità, nonché la possibilità di produrre geometrie complesse e dettagli intricati. Consente inoltre l'utilizzo di utensili e tecniche di taglio avanzati, come centri di lavoro multiasse e lavorazioni ad alta velocità, che possono migliorare ulteriormente l'efficienza e la qualità del processo.

La storia della lavorazione CNC

La sua storia risale agli anni '40, quando furono sviluppate le prime macchine a controllo numerico (NC). Nel corso del tempo, queste macchine sono diventate più diffuse e sofisticate, consentendo loro di soddisfare i requisiti di una varietà di settori, tra cui aerospaziale, automobilistico e della difesa.

Tuttavia, le vecchie macchine CNC necessitavano ancora di input manuale e avevano capacità limitate.

La trasformazione del settore manifatturiero iniziò negli anni '70 con l'introduzione dei computer, che portò a una svolta decisiva: le prime macchine CNC. Queste macchine avanzate, dotate di controlli computerizzati, erano in grado di elaborare i dati con una velocità e una precisione senza precedenti. Questa innovazione consentì agli operatori CNC di immettere i comandi direttamente nella macchina, che eseguiva automaticamente le operazioni necessarie, semplificando notevolmente il processo produttivo.

Questo fu solo l'inizio delle macchine CNC, poiché la tecnologia continuò a progredire nel corso degli anni. Lo sviluppo di software e hardware più avanzati, insieme all'introduzione di nuovi materiali e opzioni di utensili, ha aperto nuove possibilità per le unità produttive.

Oggigiorno, i macchinari CNC sono diffusi in numerosi settori e sono in grado di produrre un'ampia gamma di prodotti con elevati livelli di accuratezza e precisione.

Come funziona la lavorazione CNC?

I moderni sistemi CNC si concentrano sulla riduzione al minimo dell'intervento umano. Questo garantisce prestazioni costanti e continue, che facilitano la produzione intelligente e offrono risultati eccellenti.

Tuttavia, la produzione CNC richiede un'attenta valutazione, dalla progettazione iniziale alla produzione finale. L'intero processo si svolge in tre fasi distinte:

1 – Progettazione

Il primo passo cruciale nella lavorazione CNC coinvolge applicazioni software come CAD, CAM e CAE. Ingegneri e progettisti si affidano a questi strumenti per progettare componenti e prodotti e poi valutarne la producibilità. Questa valutazione, nota come Design for Manufacturing (DFM), è fondamentale. Garantisce che la progettazione sia ottimizzata per massimizzare l'efficienza e ridurre i costi, il tutto nel rispetto dei vincoli della tecnologia esistente.

Nella maggior parte dei casi, gli strumenti CAD disponibili sul mercato sono dotati di uno strumento CAM interno, che facilita la pre-elaborazione e la programmazione.

Dopo aver finalizzato il progetto CAD, il progettista lo converte in un formato file compatibile con CNC, in genere STEP o IGES.

2 – Pre-elaborazione e programmazione

La programmazione delle macchine CNC prevede principalmente l'utilizzo di codici G e M per comunicare con le macchine. Questi codici, generati dai pacchetti CAM, fungono da guida per il percorso dell'utensile da taglio nelle operazioni CNC.

Di solito, se un progetto rispetta gli standard DFM (Design for Manufacturing), gli operatori CNC non devono intervenire nelle fasi di pre-elaborazione o operative. Tuttavia, se il progetto non soddisfa questi standard, potrebbe essere necessario un certo livello di intervento manuale per garantire prestazioni ottimali.

La pre-elaborazione è una fase standard nella lavorazione CNC e la sua durata dipende dalla qualità del progetto. La programmazione dei codici G o M richiede in genere solo pochi minuti. Tuttavia, il successo della programmazione CNC dipende dall'aderenza del progetto alle convenzioni DFM. Progetti accurati producono codici corretti e risultati soddisfacenti, mentre difetti di progettazione portano a codici errati e risultati scadenti.

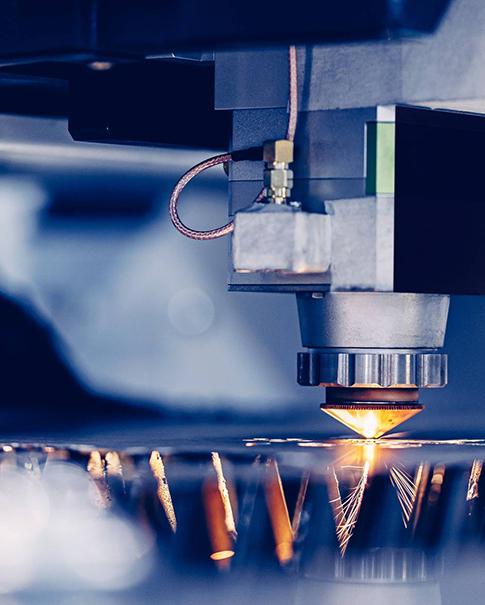

3 – Lavorazione meccanica

La fase finale è il processo di lavorazione, che utilizza i codici forniti dal passaggio precedente per rimuovere il materiale in eccesso da un blocco.

La precisione nella lavorazione degli utensili è fondamentale, ma spesso è difficile replicare le dimensioni esatte di un modello CAD. Per questo motivo, gli operatori meccanici applicano in genere le tolleranze standard ISO 2768, che variano in base ai requisiti del settore. È un principio ampiamente accettato che tolleranze più strette comportino un aumento dei costi di produzione.

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER