1. Intelligente: l'intelligenza artificiale e l'apprendimento automatico potenziano l'ottimizzazione dell'intero processo

- Lavorazione adattiva

- L'algoritmo AI analizza la forza di taglio, le vibrazioni, la temperatura e altri dati in tempo reale e regola dinamicamente la velocità di avanzamento e la velocità del mandrino per ridurre l'usura degli utensili e migliorare la precisione della lavorazione.

- Caso di studio: Siemens ha sviluppato un sistema di controllo basato sull'intelligenza artificiale che prevede la durata degli utensili e fornisce avvisi tempestivi, riducendo i tempi di fermo del 30%.

- Ottimizzazione dei parametri di processo

- I modelli di apprendimento automatico generano scenari di taglio ottimali basati sui dati storici di lavorazione, come l'ottimizzazione della strategia di evacuazione dei trucioli nella foratura di fori profondi.

- Previsione e compensazione dei difetti:

- In combinazione con la tecnologia Digital Twin, il percorso utensile viene compensato in anticipo simulando possibili distorsioni o errori durante la lavorazione.

2. Produzione ibrida: integrazione perfetta di tecnologie additive e sottrattive

- Stampa 3D + Lavorazione CNC di materiali compositi

- Produzione additiva (ad esempio, stampa 3D in metallo) per prototipazione rapida di strutture complesse, lavorazioni meccaniche di precisione CNC per la finitura superficiale e il controllo delle tolleranze.

- Un esempio concreto: la serie LASERTEC 3D di DMG MORI combina "stampa + fresatura".

- Elaborazione di materiali a gradiente

- Combinare la stampa 3D multimateriale e la tecnologia CNC per produrre parti con differenze di prestazioni locali (ad esempio superficie resistente all'usura + nucleo leggero).

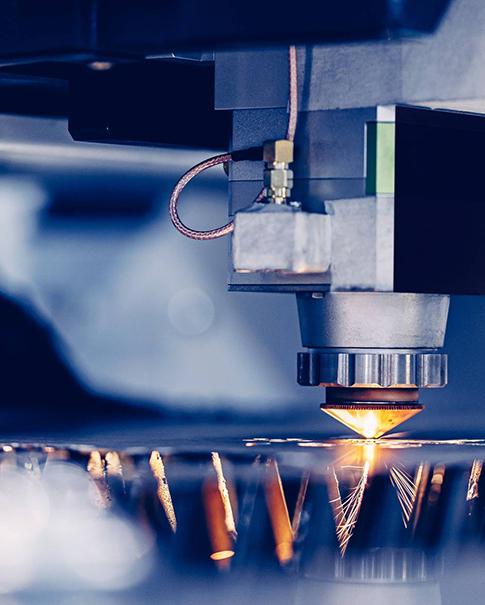

3. Lavorazione ad altissima precisione: una svolta nella precisione nanometrica

- Micro-nano processign tecnologia

- La macchina utensile nano con collegamento a 5 assi può elaborare lenti ottiche, sensori MEMS, ecc., con una rugosità superficiale pari o inferiore a Ra 1 nm.

- Applicazioni: parti di macchine per litografia di semiconduttori, parti di microrobot medicali.

- Tecnologia di raffreddamento e utensili extra

- Utensili rivestiti in diamante, tecnologia di raffreddamento ad azoto liquido a bassa temperatura per il taglio efficiente di materiali difficili da lavorare come la ceramica al carburo di silicio.

4. Produzione ecologica: il risparmio energetico e la tutela ambientale sono diventati gli indicatori chiave**

- Taglio a secco e lubrificazione minima (MQL):

- Ridurre del 90% l'uso del fluido da taglio, ridurre i costi di smaltimento dei liquidi di scarto e l'inquinamento ambientale.

- Sistema di recupero energetico

- L'energia di frenata della macchina utensile viene reimmessa nella rete elettrica, riducendo il consumo energetico del 15%~20%.

5. Produzione flessibile: risposta efficiente per piccoli lotti e varietà multiple

- Progettazione modulare della macchina:

- Cambiare rapidamente mandrini, magazzini utensili e attrezzature per soddisfare le diverse esigenze di lavorazione dei pezzi.

- Produzione collaborativa nel cloud

- Attraverso la piattaforma Internet industriale, il programma di elaborazione può essere rilasciato da remoto e lo stato delle apparecchiature di fabbrica globali può essere monitorato.

- Caso di studio: il sistema FIELD di FANUC supporta l'interconnessione di dispositivi multimarca.

- Cambi guidati da Digital Twin:

- La tecnologia di messa in servizio virtuale riduce i tempi di cambio produzione di oltre il 50%, risultando particolarmente adatta alla produzione personalizzata di apparecchiature mediche.

6. Collaborazione uomo-robot: dall'automazione all'autonomia**

- Integrazione del robot collaborativo (Cobot):

- I robot sono responsabili del carico e dello scarico, dei test, le macchine utensili CNC si concentrano sulla lavorazione ad alto valore e la collaborazione uomo-macchina migliora l'efficienza.

- Applicazione: la linea di produzione dei ricambi auto non è presidiata 24 ore al giorno.

- Operazioni e formazione assistite da AR/VR

- Gli occhiali per realtà aumentata aiutano i lavoratori a padroneggiare rapidamente le operazioni complesse delle macchine, riducendo i cicli di formazione.

- Sistema di Decisione Autonomo

- Elaborazione dei dati in tempo reale basata sull'edge computing: la macchina può scegliere autonomamente il percorso utensile o richiedere la manutenzione.

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER