Spiegazione del refrigerante CNC: tipi, manutenzione e sicurezza

Sep 30, 2025

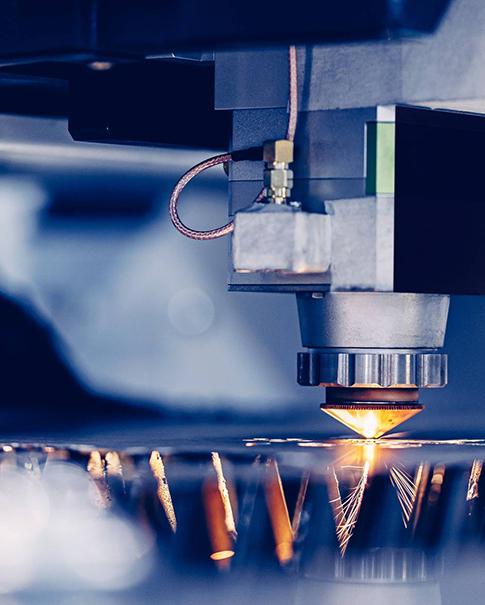

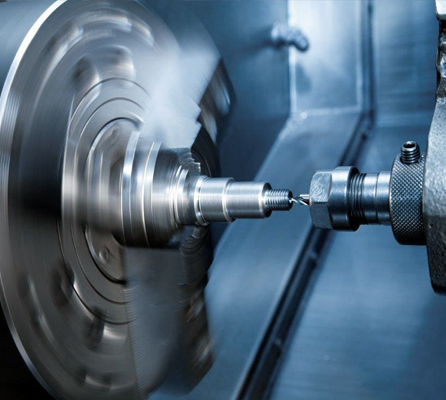

Il refrigerante non è solo un liquido che schizza intorno alla macchina CNC, è la differenza tra un taglio pulito e preciso e un pezzo scartato. Nella lavorazione meccanica, il refrigerante CNC, che si tratti di un fluido da taglio, di una nebbia o di un lubrificante specifico, mantiene il calore sotto controllo, prolunga la durata dell'utensile e facilita l'eliminazione dei trucioli. Un errore comune? Si pensa che l'unico compito del refrigerante sia quello di raffreddare. In realtà, fa molto di più: lubrifica l'utensile, elimina i trucioli e persino migliora la finitura superficiale. Se si sceglie il refrigerante giusto, non si rischiano solo picchi di temperatura, ma anche la geometria, la nitidezza del pezzo e la sicurezza dell'operatore.

La scelta del refrigerante giusto per le macchine CNC non è solo un dettaglio tecnico, ma influisce sulla precisione, sulla qualità dei pezzi, sulla sicurezza dell'operatore e sui costi complessivi del progetto. Una scelta sbagliata può comportare bordi bruciati, utensili smussati e continui tempi di fermo macchina.

In Keso, non ci limitiamo a parlare di teoria: i nostri operatori eseguono quotidianamente configurazioni di refrigerante e questa guida trae spunto direttamente dalla loro esperienza in officina. Che tu stia tagliando alluminio, acciaio o plastica, queste informazioni ti aiuteranno a capire l'impatto reale del refrigerante sul processo di lavorazione.

Tipi di refrigerante per macchine CNC e relativi utilizzi

(Istock)

Non tutti i refrigeranti per macchine CNC sono uguali e gli operatori hanno spesso opinioni molto discordanti su quali siano effettivamente efficaci nel mondo reale. La scelta si riduce al bilanciamento tra raffreddamento e lubrificazione e alla scelta della miscela giusta per il materiale.

Refrigeranti a base d'acqua vs. a base di olio

Tipo

Punti di forza

Punti deboli

Ideale per

A base d'acqua

Ottimo raffreddamento, lavaggio dei trucioli, meno costoso

Lubrificazione inferiore, rischio di ruggine se gestita male

Alluminio, plastica, lavorazioni meccaniche generali

A base di olio

Lubrificazione superiore, protegge i bordi degli utensili

Scarso raffreddamento, può fare fumo ad alte velocità

Acciaio, titanio, taglio pesante

Opzioni di olio sintetico, semisintetico e puro

Refrigeranti sintetici —> Completamente a base d'acqua, senza olio. Ottimi per il controllo del calore e la visibilità, ma meno lubrificanti.

Refrigeranti semisintetici —> Una miscela di acqua e olio. Un'opzione "di mezzo" adatta alla maggior parte delle officine.

Oli puri (oli lisci) —> olio al 100%, imbattibile per la durata dell'utensile e la finitura superficiale su metalli resistenti, ma disordinato e costoso da gestire.

Cosa dicono i macchinisti

Nei forum dedicati alla lavorazione meccanica e nelle officine, si sente molto parlare di lealtà verso le officine aerospaziali per la stabilità. Le preferenze variano, ma il tema è chiaro: scegli un refrigerante che si adatti al tuo carico di lavoro, non solo al tuo budget.

In lavorazione ad alta velocitàLa scelta del refrigerante non riguarda solo il mantenimento del freddo degli utensili, ma determina anche se si ottiene una finitura pulita o una rapida usura dell'utensile.

Con quale frequenza dovresti cambiare il refrigerante CNC?

(Istock)

Non esiste un orario preciso per la sostituzione del refrigerante: dipende dalle dimensioni dell'officina, dal mix di materiali e dalla frequenza di funzionamento delle macchine.

Officine di produzione ad alto volume di solito è necessario rinnovare o cambiare il liquido refrigerante ogni 6-12 settimane, poiché la miscela si degrada più rapidamente con l'uso continuo.

Officine di medie dimensioni può spesso estendersi fino a 3-6 mesi se si continua a monitorare e filtrare.

Negozi di prototipazione o a basso volume a volte utilizzare lo stesso liquido di raffreddamento per 6-12 mesi, ma solo se sottoposto a corretta manutenzione.

Segnali che indicano che è necessario cambiare il liquido di raffreddamento

Quell'odore rancido e aspro Ciò che fa venire il vomito ai macchinisti è la crescita batterica.

Fanghi o residui oleosi galleggianti in superficie.

Un visibile “fioritura” (formazione di schiuma o torbidità) causata da batteri incontrollati.

Gli strumenti sono smorzamento più velocemente del solito, oppure i pezzi escono con una finitura superficiale scadente.

Cosa consigliano i nostri ingegneri

I nostri macchinisti mantengono sano il refrigerante con semplici abitudini:

Aerazione per mantenere il flusso di ossigeno e ridurre i batteri.

Sistemi di filtrazione che raccolgono trucioli fini e disperdono olio.

Miscelazione con acqua RO/DI invece di acqua del rubinetto per evitare l'accumulo di minerali.

Se non hai tempo di prenderti cura del tuo refrigerante, non preoccuparti. Molte officine esternalizzano semplicemente la lavorazione CNC a servizi come Keso, dove manutenzione, monitoraggio e preparazione della macchina sono già inclusi nel processo.

Manutenzione del sistema di raffreddamento: filtri e ugelli

(Istock)

Un sistema di raffreddamento CNC è efficace quanto il suo punto debole. Anche il fluido di qualità più elevata non funzionerà se filtri, ugelli o pompe vengono trascurati. Una corretta manutenzione non solo prolunga la durata del refrigerante, ma previene anche l'usura degli utensili, problemi di finitura superficiale e costosi tempi di fermo macchina.

Scelta della corretta configurazione del filtro del refrigerante CNC

I filtri proteggono la pompa e gli ugelli da trucioli, particelle fini e olio di scarto. La configurazione corretta dipende dal materiale da tagliare e dal ciclo di lavoro della macchina:

Filtri a sacco: Conveniente ed efficace per carichi di trucioli da leggeri a medi.

Separatori a ciclone: Ideale per negozi con grandi volumi di lavoro che trattano particelle fini.

Filtri magnetici: Essenziale se si lavorano materiali ferrosi.

Molti negozi combinano queste soluzioni per una protezione a strati, assicurando che sia i trucioli di grandi dimensioni sia le particelle microfini vengano catturate prima che raggiungano le parti critiche del sistema.

Importanza del posizionamento e dei tipi di ugelli

L'erogazione del refrigerante è un'arte. Gli ugelli devono colpire il tagliente dell'utensile con precisione, se non sono troppo lontani, si rischia solo di allagare l'area di lavoro senza alcun effetto. Le soluzioni più comuni includono:

Mod Loc-Line: Flessibile, economico e facile da riposizionare.

Ugelli ad alta pressione: Garantisce una penetrazione profonda per foratura, maschiatura e materiali temprati.

Ugelli nebulizzatori/nebbia: Utile quando il liquido di raffreddamento è eccessivo ma la lubrificazione è comunque necessaria.

Regolare la direzione dell'ugello può migliorare notevolmente l'evacuazione dei trucioli e la finitura superficiale. Alcuni operatori sperimentano persino modifiche agli ugelli stampate in 3D per ottenere geometrie personalizzate.

Suggerimenti per la salute della pompa

La pompa del refrigerante è il cuore del sistema e la sua negligenza può causare l'ostruzione delle giranti o addirittura il guasto completo della pompa. Le principali procedure da seguire includono:

Pulizia regolare: Rimuovere i residui di trucioli e gli accumuli di trucioli dalla coppa dell'olio.

Ispezionare le giranti: Le lame danneggiate riducono il flusso e la pressione, compromettendo la durata dell'utensile.

Evitare l'intasamento dei fanghi: Utilizzare deflettori o protezioni anti-schegge per tenere i detriti più grandi lontani dall'aspirazione della pompa.

Se sottoposto a manutenzione corretta, un sistema di raffreddamento funziona in modo pulito, efficiente e prevedibile, lasciandoti libero di concentrarti sui tempi di ciclo e sulle tolleranze anziché sulle ricostruzioni di emergenza della pompa.

Buone pratiche per l'uso di refrigeranti e lubrificanti per macchine CNC

(Istock)

Il refrigerante per macchine CNC è una scienza di rapporti, qualità dell'acqua e disciplina. Ecco come utilizzarlo correttamente:

Livelli di concentrazione target: La maggior parte dei refrigeranti idrosolubili funziona meglio tra l'8 e il 12%, ma è necessario apportare modifiche in base al materiale. L'alluminio spesso preferisce la percentuale più bassa per superfici pulite, mentre le leghe più dure potrebbero richiedere miscele più ricche per la lubrificazione.

Utilizzare acqua deionizzata (DI): Utilizzare acqua osmotica o deionizzata mantiene la vasca di raccolta più pulita, riduce le incrostazioni minerali e prolunga significativamente la durata del refrigerante. L'acqua dura del rubinetto può far risparmiare tempo all'inizio, ma si tradurrà in depositi e guasti prematuri.

Evita gli errori più comuni:

Una concentrazione eccessiva provoca residui appiccicosi e incrostazioni negli utensili.

La contaminazione incrociata (miscelazione di marche diverse o rabbocco con un fluido sbagliato) destabilizza le emulsioni.

L'utilizzo di un tipo di refrigerante sbagliato per il lavoro, come ad esempio olio intero quando è richiesto un flusso sintetico, può creare fumo, nebbia o addirittura danneggiare l'utensile.

In breve, trattate il refrigerante come un materiale di consumo che merita precisione, non congetture. Un utilizzo troppo magro o con una filtrazione inadeguata può accelerare l'usura dei taglienti e la formazione di microscheggiature. Per un approfondimento sull'individuazione precoce dei segnali di allarme, leggete la nostra guida al rilevamento e alla manutenzione dell'usura degli utensili nella lavorazione CNC.

Salute e sicurezza: il refrigerante CNC è pericoloso?

(Istock)

Il refrigerante per CNC mantiene in vita le macchine, ma gli operatori sanno che comporta dei compromessi. L'esposizione prolungata alla nebbia di refrigerante o il contatto con la pelle possono comportare dei rischi:

Nebbia e inalazione: L'esposizione continua alla nebbia può causare tosse, irritazione o problemi respiratori a lungo termine. Le officine che utilizzano sistemi ad alta pressione dovrebbero prendere in considerazione l'uso di collettori di nebbia e respiratori elettroventilati.

Esposizione della pelle: La dermatite è comune quando non si utilizzano guanti o creme protettive. Proteggete sempre le mani, soprattutto con oli puri e vecchie formulazioni.

Irritanti chimici: Alcuni refrigeranti contengono biocidi e stabilizzanti che, pur essendo efficaci, possono causare reazioni dopo un'esposizione prolungata.

I forum dedicati ai meccanici del mondo reale condividono spesso storie ammonitrici: "tosse da scarico", eruzioni cutanee croniche e mal di testa da film oleoso. La morale della favola è investire in una buona ventilazione, DPI e igiene del serbatoio: polmoni e pelle vi ringrazieranno.

Risoluzione dei problemi comuni del refrigerante CNC

(Istock)

Noi di Keso abbiamo visto entrambe le cose. Alcuni clienti si affidano completamente ai problemi del refrigerante: esternalizzare il servizio di smaltimento e rabbocco fa risparmiare loro giorni di fermo macchina all'anno. Altri si limitano a consultarci per ricette ottimizzate per il refrigerante che prolungano la durata della coppa dell'olio. In entrambi i casi, il contributo degli esperti di solito si ripaga da solo. Puoi richiedere oggi stesso un preventivo gratuito per i nostri servizi di lavorazione CNC, perché anche i migliori sistemi di raffreddamento possono avere problemi, ma ecco cosa fare quando le cose si mettono male:

La pompa si surriscalda o si blocca: Solitamente si tratta di un problema di accumulo di fanghi. Lavare la vasca di raccolta, pulire le giranti e valutare l'aggiunta di un sistema di filtraggio migliore prima di riavviare.

Separazione o colorazione: Le emulsioni che si decompongono spesso sono causate da problemi di durezza dell'acqua o da incompatibilità di marca. A volte cambiare marca di refrigerante funziona, ma la filtrazione e l'acqua deionizzata di solito risolvono la causa principale.

Batteri, odori e pellicola: Il temuto "pozzetto rancido". Risolvilo con: Skimmer a dischi per l'olio di scarto. Sistemi di aerazione per impedire ai batteri di proliferare in modo anaerobico. Pulizia programmata del pozzetto prima che la fioritura diventi catastrofica.

Pensate alla cura del refrigerante come alla cura della macchina: la negligenza provoca cattivi odori, macchie e tempi di inattività.

Quando scegliere servizi di raffreddamento CNC professionali rispetto al fai da te

La manutenzione del refrigerante spesso rientra tra le priorità delle officine più impegnate. Tuttavia, decidere tra la manutenzione interna e l'outsourcing può rivelarsi una scelta strategica:

Fai da te in casa: Costi inferiori se si dispone della manodopera necessaria, ma richiede formazione, test regolari e disciplina. Se si salta un passaggio, la vasca di raccolta si trasforma in un rischio biologico.

Servizi professionali: Più costoso all'inizio, ma fa risparmiare ore di fermo e garantisce prestazioni costanti del refrigerante. Alcuni fornitori si occupano di smaltimento sicuro, aggiornamenti della filtrazione e miscele di refrigerante personalizzate.

Suggerimenti di progettazione: ottimizzazione del flusso del refrigerante e del posizionamento degli ugelli

Un design intelligente può fare la differenza:

Posizionamento dell'ugello: Puntare sempre all'utensile e all'interfaccia del truciolo. Gli ugelli regolabili multipli consentono di adattarsi ai cambi di utensile senza dover reimpostare l'intera configurazione.

Refrigerante attraverso il mandrino: Ideale per forature profonde e grandi volumi di evacuazione dei trucioli. Sebbene costoso, può raddoppiare la durata dell'utensile nelle operazioni più impegnative.

Alta pressione vs. inondazione:

Il refrigerante Flood è economico, affidabile e funziona bene per la fresatura in generale.

I sistemi ad alta pressione sono ideali per le leghe aerospaziali e per applicazioni di perforazione lunga, ma richiedono una maggiore manutenzione della pompa.

Una buona regola pratica? Fai attenzione ai trucioli. Se non si schiariscono, l'ugello non funziona correttamente..

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER