Nel mondo della produzione, "Più grande è meglio" non è l'unica verità. Dagli impianti medicali e componenti microelettronici agli ingranaggi di precisione e alle apparecchiature ottiche nel settore aerospaziale, la domanda di componenti minuscoli e altamente complessi sta crescendo in modo esponenziale. La tecnologia chiave che soddisfa questa domanda è la microlavorazione CNC. Si tratta di un'arte manifatturiera di precisione che riduce in modo incredibile la potenza delle tradizionali lavorazioni CNC (Computer Numerical Control).

Questo articolo vi condurrà in un'immersione profonda nel mondo della lavorazione micro-CNC, esplorando la sua esclusiva maestria artigianale, i sorprendenti livelli di precisione e le dimensioni ridotte dei pezzi che può produrre.

Che cosa è la microlavorazione CNC?

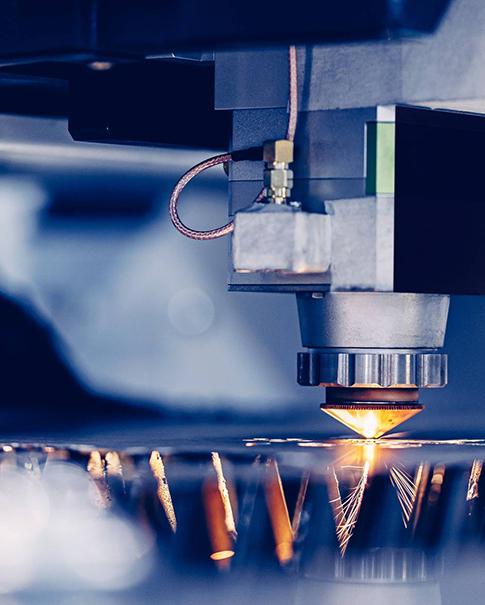

La microlavorazione CNC è essenzialmente una lavorazione sottrattiva. Rimuove gradualmente materiale da un materiale solido (definito "grezzo") tramite macchine utensili di precisione controllate da computer, formando infine una forma geometrica progettata. La differenza fondamentale tra questa lavorazione e quella CNC tradizionale risiede nelle dimensioni, nella precisione e nel livello di dettaglio.

In genere, quando le dimensioni delle caratteristiche di un componente sono inferiori a 100 micrometri (0,1 millimetri) o il requisito di tolleranza raggiunge il livello di ± diversi micrometri, si parla di microlavorazione. Questa non solo richiede macchine utensili ultraprecise, ma impone anche requisiti estremi agli utensili da taglio, all'ambiente e al controllo di processo.

Il processo e le tecnologie chiave della microlavorazione CNC

Il processo di base della microlavorazione è simile a quello del CNC tradizionale: progettazione CAD → programmazione CAM → impostazione della macchina utensile → lavorazione → ispezione. Ma ogni fase è piena di sfide uniche.

- Macchine utensili ad altissima precisione: le micro macchine utensili CNC sono meraviglie dell'ingegneria. Solitamente presentano:

Velocità del mandrino estremamente elevata: la velocità del mandrino può raggiungere i 30.000-160.000 giri/min o anche di più. L'elevata velocità di rotazione consente l'utilizzo di utensili da taglio estremamente piccoli (con diametri potenzialmente inferiori a quelli di un capello umano), mantenendo una velocità di taglio sufficiente a garantire una forza di taglio minima e una finitura superficiale perfetta.

· Piattaforma di movimento ultra-precisa: utilizzando motori lineari e righelli a reticolo ad alta risoluzione, è in grado di raggiungere una precisione di movimento e posizionamento submicronica (meno di 1 µm). Ogni piccolo movimento della macchina utensile deve essere preciso e privo di errori.

· Rigidità e stabilità eccezionali: nonostante le dimensioni ridotte dei pezzi, la macchina utensile stessa deve essere estremamente robusta e resistente alle vibrazioni. Qualsiasi lieve sbalzo termico o vibrazione distruggerà direttamente i pezzi. Pertanto, le macchine utensili sono solitamente installate su piattaforme antivibranti e si trovano in un ambiente con rigorosi controlli di temperatura e umidità.

2. Microutensili da taglio: questa è l'anima della microlavorazione. I diametri di questi utensili da taglio (principalmente frese a candela) possono essere piccoli fino a 0,1 millimetri (100 micrometri) o anche più piccoli. Per una comprensione intuitiva, il diametro medio di un capello umano è di circa 75 micrometri. Questi utensili da taglio non sono solo estremamente difficili da produrre, ma anche estremamente fragili, imponendo requisiti rigorosi per il serraggio, l'impostazione degli utensili e i parametri di taglio.

3. Software e controllo avanzati: il software CAM deve essere in grado di generare percorsi utensile per l'elaborazione di feature a livello di micron. Durante la programmazione, è necessario prestare particolare attenzione alla fragilità dell'utensile da taglio. È necessario adottare strategie di taglio più intelligenti, come la fresatura di precisione (Peck Milling) e velocità di avanzamento più ottimizzate, per prevenire la rottura dell'utensile e garantire la precisione.

4. Materiali professionali: Micro CNC può elaborare vari materiali, tra cui:

· Metalli: alluminio, acciaio inossidabile, lega di titanio (comunemente utilizzata negli impianti medici), ottone, lega di nichel.

· Plastiche: PEEK, ABS, policarbonato, ULTEM.

· Altri: Ceramica, materiali compositi. Il materiale deve avere una microstruttura uniforme. Eventuali impurità possono causare scheggiature degli utensili da taglio o difetti nei componenti.

Un livello di precisione sorprendente

La precisione della microlavorazione CNC è il fondamento della sua esistenza. Le sue capacità sono solitamente misurate dai seguenti indicatori:

· Tolleranza: la tolleranza convenzionale può raggiungere ±5 micron (±0,005 millimetri) e, su macchine utensili ad alta precisione, può raggiungere anche una tolleranza di ±1 micron.

· Finitura superficiale: può ottenere una finitura a specchio di Ra < 0,1 micron e non è richiesta quasi nessuna lucidatura secondaria.

· Dimensioni delle caratteristiche: può produrre stabilmente caratteristiche con una larghezza e una dimensione dei pori pari a 25-50 micron.

Quanto può essere piccolo? Esplora i limiti delle dimensioni

Quindi, dov'è esattamente il limite della micro-lavorazione CNC? Ecco alcuni esempi concreti che ne dimostrano le capacità quasi magiche:

· Più sottile di un capello umano: può creare scanalature e fusti più piccoli, più stretti del diametro di un capello umano (~75µm).

· Microingranaggi: è possibile realizzare ingranaggi interamente in metallo per microrobot o strumenti di precisione, con profili dei denti perfetti e spaziature estremamente ridotte. L'intero ingranaggio può avere le dimensioni di una punta di ago.

Stent medici: i dispositivi medici come gli stent vascolari sono solitamente realizzati con tubi tagliati al laser, ma è possibile utilizzare la micro-CNC per elaborare i loro connettori complessi o realizzare prototipi.

· Chip microfluidico: una complessa rete di canali più sottile di un capello umano viene realizzata su un blocco di plastica o metallo per l'analisi biochimica.

· Componenti ottici: produzione di minuscole matrici di lenti, connettori in fibra ottica e altri componenti ottici di precisione che richiedono una precisione superficiale a livello nanometrico.

· Componenti dell'orologio: molti piccoli ingranaggi, forcelle di scappamento e ponti degli orologi meccanici di alta gamma si basano sulla tecnologia di microlavorazione.

Sebbene alcune tecnologie (come la fotolitografia) possano produrre strutture nanometriche più piccole, il vantaggio unico della micro-CNC risiede nella sua capacità di produrre direttamente parti metalliche e plastiche realmente tridimensionali e funzionali con materiali ingegneristici, e presenta eccellenti proprietà meccaniche e geometrie complesse.

Campo di applicazione

La microlavorazione CNC è una parte indispensabile di molti settori ad alta tecnologia:

· Scienze mediche e della vita: strumenti chirurgici, impianti, parti endoscopiche, dispositivi microfluidici.

· Aerospaziale e difesa: microsensori, giroscopi, componenti leggeri, parti di veicoli aerei senza pilota.

· Elettronica e semiconduttori: connettori, dissipatori di calore, dispositivi di prova, stampi per il confezionamento di chip.

· Ottica e fotonica: supporti per lenti, tubi a infrarossi, componenti laser.

· Industria automobilistica: microsensori, componenti del sistema di iniezione del carburante.

Conclusione

La lavorazione micro-CNC rappresenta l'apice della tecnologia di produzione sottrattiva. Combina la precisione del controllo computerizzato con la massima maestria dell'ingegneria meccanica, creando miracoli su scale difficili da vedere chiaramente a occhio nudo. Non si tratta semplicemente di rendere le cose più piccole, ma piuttosto di realizzare grandi sogni ingegneristici in modo affidabile e ripetibile nel mondo microscopico, spingendo i confini dell'innovazione in vari settori, dalla sanità all'elettronica di consumo. Con il continuo progresso della tecnologia e dei materiali, in futuro assisteremo sicuramente alla creazione di microcomponenti più piccoli, più complessi e più intelligenti.

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER