Informazioni sulla lavorazione CNC

Apr 11, 2025

Che cosa è la lavorazione CNC?

CNC è l'acronimo di Computer Numerical Control, quindi la lavorazione CNC può essere definita come un processo di produzione in cui un codice di calcolo controlla i parametri del processo, tra cui:

Movimento della testa della macchina utensile.

Movimento della parte o avanzamento.

Velocità di rotazione.

Selezione degli utensili per teste multiutensile.

Quantità di refrigerante, se necessario.

In parole semplici, significa utilizzare la potenza di calcolo per controllare e monitorare tutti i movimenti necessari di una macchina per produrre parti a partire da materie prime.

Come funziona la lavorazione CNC?

In pratica, il programma CNC fornisce comandi che la macchina può leggere e comprendere. Questi comandi indicano ai motori della macchina quando e come muovere i componenti corrispondenti per ottenere i risultati desiderati.

Le prime macchine CNC utilizzavano schede perforate con codice scritto e avevano una flessibilità limitata per il movimento dell'utensile.

Tuttavia, le attuali macchine CNC possono essere associate a software CAD/CAM (Computer Aided Design/Computer Aided Manufacturing). Ciò significa che il progettista può creare un modello 3D del pezzo e quindi tradurre i parametri del pezzo in un programma CNC tramite il software CAM.

Questo programma finale, creato dal software CAM, viene inserito nella macchina e il processo di produzione ha inizio. Il pezzo è pronto quando la macchina termina l'esecuzione del programma.

Un altro aspetto importante delle attuali e più sofisticate macchine CNC è la loro flessibilità, poiché possono muoversi in un intervallo di 2,5 assi, 3 assi o 5 assi a seconda del tipo di macchina.

Lavorazione CNC per legnoMentre molti potrebbero pensare che la lavorazione del legno sia un'arte riservata solo agli intagliatori più esperti, la verità è che la lavorazione CNC del legno consente un lavoro più efficiente, anche per i progetti più complessi.

Con la lavorazione CNC del legno è possibile produrre pezzi di grandi dimensioni in tempi più rapidi. Permette inoltre al falegname di mantenere intatte la bellezza naturale e la resistenza del legno utilizzato, cosa difficile da ottenere con altri tipi di macchine per la lavorazione del legno.

Altri vantaggi derivanti dall'utilizzo della lavorazione CNC per il legno sono:

È possibile realizzare con facilità anche forme complesse, troppo difficili da realizzare manualmente.

Maggiore precisione e tempi di produzione più brevi.

Maggiore efficienza e riduzione degli sprechi di materiale.

Aumento della redditività.

Lavorazioni CNC per il settore medicoÈ noto che il settore medicale è molto esigente e richiede il rispetto di tutti gli standard richiesti. È il caso delle lavorazioni CNC per il settore medicale.

Fortunatamente, come accennato in precedenza, i principali vantaggi della lavorazione CNC sono l'elevata efficienza e l'elevata precisione che non lasciano praticamente alcun margine di errore.

Questo rende la lavorazione CNC per l'industria medicale la migliore opzione produttiva del settore, essendo la lavorazione di precisione l'alternativa scelta per soddisfare i rigorosi requisiti di tolleranza. Altri requisiti comuni includono:

Geometrie complesse che solitamente richiedono macchine a 5 assi.

Livelli di pulizia molto elevati.

Possibilità di lavorare diversi materiali speciali.

Finitura superficiale di altissimo livello.

Le applicazioni comuni della lavorazione CNC per il settore medico includono:

Impianti e protesi.

Strumenti chirurgici.

Componenti elettronici per apparecchiature mediche.

Microdispositivi medicali che richiedono microlavorazione.

Lavorazione CNC per fusioneLa fusione è un processo di produzione che dipende dalla qualità degli stampi utilizzati per ottenere i risultati desiderati. Ciò significa che è fondamentale selezionare il processo migliore per la produzione degli stampi.

La lavorazione CNC per la fusione su macchine a 5 assi riduce la possibilità di errori dovuti allo spostamento del getto tra le diverse fasi di lavorazione. Questa riduzione degli errori consente di ottenere getti con tolleranze estremamente ristrette.

Un'altra buona applicazione della lavorazione CNC per la fusione è che la maggior parte dei getti richiede una post-lavorazione per migliorare la finitura superficiale. La lavorazione CNC per la fusione permette di ottenere la finitura superficiale desiderata in modo rapido ed efficiente.

Inoltre, la lavorazione CNC può gestire il tipo di materiali comunemente utilizzati per le fusioni come l'alluminio, che può rappresentare un problema per altri problemi di produzione.

Lavorazione CNC per alluminio

Essendo un metallo leggero, l'alluminio è il materiale preferito per molte applicazioni, in particolare nei settori automobilistico e aerospaziale. Tuttavia, il suo utilizzo in alcune di queste applicazioni richiede forme molto complesse.

Inoltre, potrebbero essere necessarie parti sottili, il che aumenta il rischio di deformazione a causa della bassa durezza e dell'elevata dilatazione termica del materiale.

È qui che la lavorazione CNC dell'alluminio diventa importante. La lavorazione CNC a 5 assi per l'alluminio offre vantaggi quali:

È semplice da configurare, il che riduce i tempi di consegna e migliora l'efficienza

Permette di lavorare con geometrie complesse grazie alla capacità di evitare collisioni con il portautensile durante l'inclinazione del tavolo di lavoro o con l'utensile da taglio.

Può utilizzare utensili più corti e più rigidi, alcuni con velocità del mandrino elevate, ottenute riducendo il carico sull'utensile da taglio.

I pezzi non devono passare attraverso diverse postazioni di lavoro, il che significa che gli errori vengono ridotti, la precisione aumenta e la qualità è garantita.

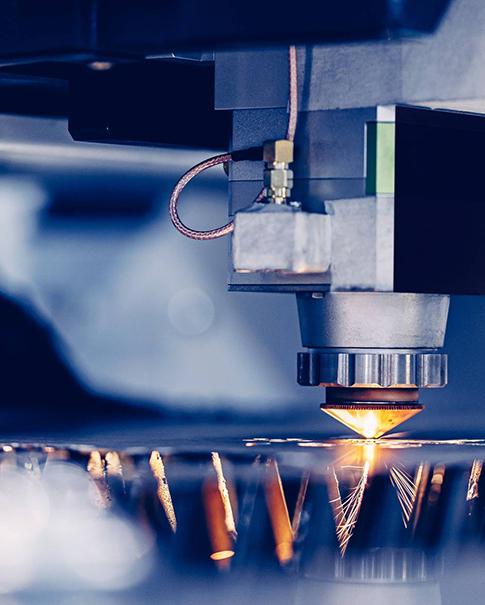

Queste macchine possono utilizzare altre alternative come il taglio a getto d'acqua o il taglio laser, che eliminano i problemi legati alla lavorazione di pezzi di alluminio molto sottili.

Lavorazione CNC per parti aerospaziali

Considerato il numero di componenti necessari per assemblare un aereo e la complessità di tali componenti, è chiaro che l'industria aerospaziale richiede la massima precisione ed efficienza possibili da un processo di produzione.

Per questo motivo, la lavorazione CNC per componenti aerospaziali ha acquisito sempre più popolarità ed è ora l'opzione preferita per la produzione di componenti aerospaziali.

La lavorazione CNC per componenti aerospaziali deve soddisfare requisiti complessi quali:

Lavorare con pareti sottili.

Limitare la deformazione del materiale, ad esempio quando si lavora con alluminio e altri materiali leggeri.

Lavorare con geometrie curve e complesse.

D'altro canto, la lavorazione CNC è l'opzione migliore per la produzione di componenti aerospaziali poiché offre i seguenti vantaggi:

È un processo conveniente.

Può fornire risultati di alta qualità.

Può funzionare con progetti personalizzati.

Garantisce elevata accuratezza e precisione ingegneristica.

Riduce e talvolta elimina l'errore umano.

Può produrre geometrie complesse.

Lavorazione CNC per gioielli

In passato, i gioielli venivano realizzati esclusivamente a mano da abili artigiani. Tuttavia, oggi non è più così, poiché sempre più produttori di gioielli stanno implementando metodi per migliorare la propria efficienza e aumentare la redditività.

Esistono diversi modi in cui la lavorazione CNC per la gioielleria può aiutare gli artigiani e i produttori di gioielli in generale. I vantaggi più comuni riscontrati sono:

Crea facilmente modelli master per la fusione dei gioielli.

Crea rapidamente stampi per fusione con elevata precisione.

Utilizzando sofisticate macchine CNC, è possibile realizzare raffinati gioielli finiti.

Crea incisioni personalizzate in modo rapido e preciso.

Rifinitura semplice dei gioielli tramite processi di sfaccettatura del marmo e lucidatura dei gioielli.

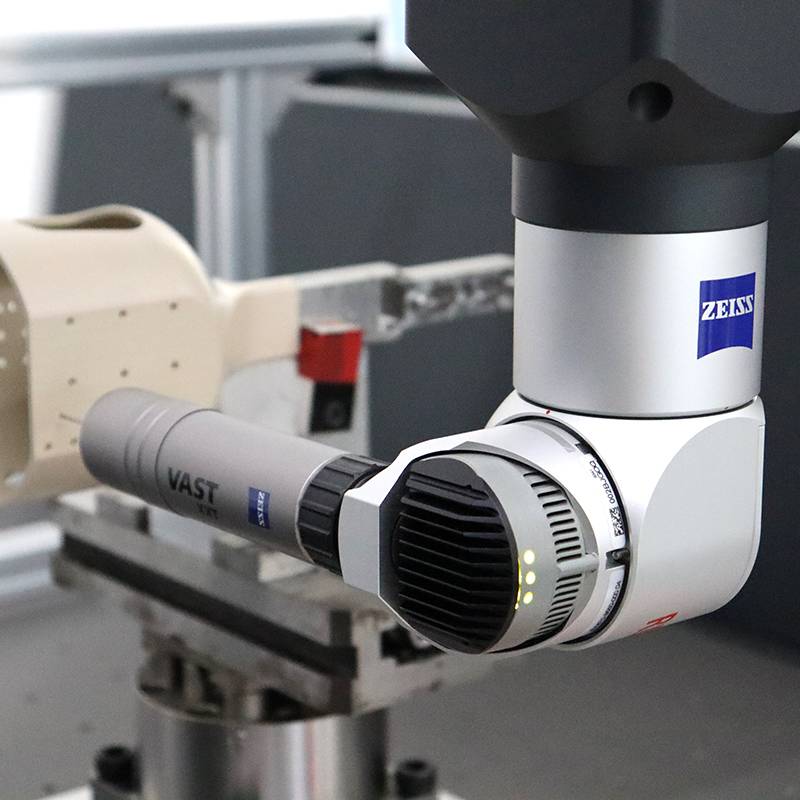

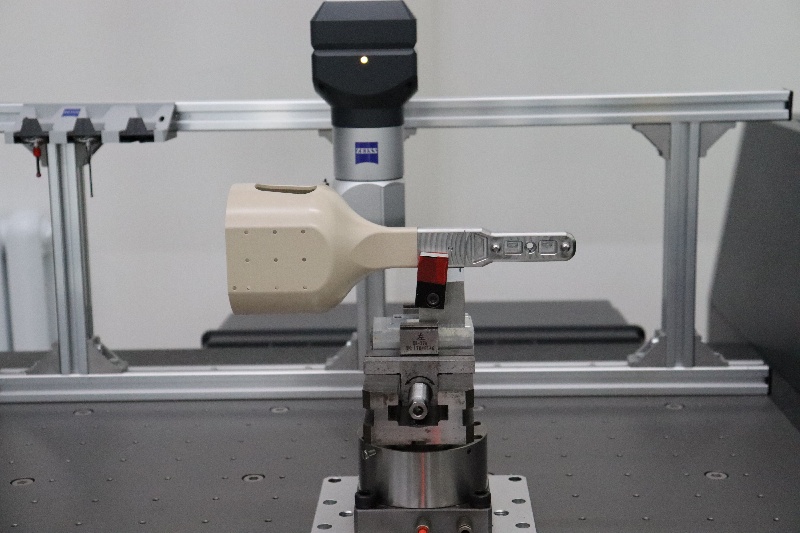

Tolleranze di lavorazione CNC

È vero che la lavorazione CNC ha portato la precisione di produzione a livelli elevatissimi. Tuttavia, come accade con altri processi produttivi, le dimensioni del prodotto finale non sono mai perfette. Ed è qui che le tolleranze della lavorazione CNC giocano un ruolo importante.

È importante ricordare che le tolleranze rappresentano la massima variazione consentita per le stesse dimensioni di due pezzi della stessa serie. Di solito vengono definite in fase di progettazione.

Ci sono diversi aspetti da considerare quando si impostano le tolleranze richieste:

Componenti di accoppiamento.

Tipologia di materiali.

Processi di produzione disponibili.

Solitamente, tolleranze più strette sono più costose da ottenere.

Le tolleranze vengono solitamente classificate in base al loro grado di rigore nei seguenti gruppi:

Tolleranze ridotte.

Tolleranze medie.

Tolleranze grossolane.

Tolleranze molto grossolane.

In generale, i limiti per ciascun gruppo sono stabiliti in base agli standard internazionali, tra cui ANSI B4.1, ANSI B4.2, ISO 286, ISO 1829, ISO 2768, EN 20286 e JIS B 0401.

Per le tolleranze di lavorazione CNC, i limiti standard sono compresi tra ± 0,005" o 0,13 mm. Tuttavia, alcuni servizi molto sofisticati affermano di poter fornire tolleranze di lavorazione CNC fino a ± 0,0025 mm.

Ecco alcune tolleranze standard per la lavorazione CNC a seconda del processo CNC:

Tornio — ±0,005″ (0,13 mm)

Fresatrice — ± 0,005″ (0,13 mm)

Fresatura a 3 assi — ± 0,005″ (0,13 mm)

Fresatura a 5 assi — ± 0,005″ (0,13 mm)

Incisione — ± 0,005″ (0,13 mm)

Planarità — ± 0,010″ (0,25 mm)

ISCRIVITI ALLA NOSTRA NEWSLETTER

ISCRIVITI ALLA NOSTRA NEWSLETTER